Combined Fluorescence and Phosphorescence Lifetime

Imaging (FLIM / PLIM) with the Zeiss LSM 710 NLO Microscopes

Wolfgang Becker, Stefan Smietana, Axel Bergmann,

Becker & HIckl GmbH, Berlin, Germany

The PLIM

technique described here is based on modulating the titanium-sapphire laser of

a multiphoton microscope by a signal synchronous with the pixel clock of the

scanner, and recording the fluorescence and phosphorescence signals by

multi-dimensional TCSPC [1]. Fluorescence is recorded during the on-phase of

the laser, phosphorescence during the off-phase. Laser modulation is achieved

by controlling the the AOM of the laser scanning microscope by a signal

generated in the TCSPC system. This document contains instructions of how to set

the parameters of the bh SPC‑150 or SPC‑830 FLIM systems for

combined fluorescence (FLIM) and phosphorescence lifetime imaging (PLIM). It

should be considered a supplement to the bh TCSPC Handbook [1] and the bh

Handbook of the FLIM systems for the Zeiss LSM 510 and 710 laser scanning

microscopes [2].

Principle and System Architecture

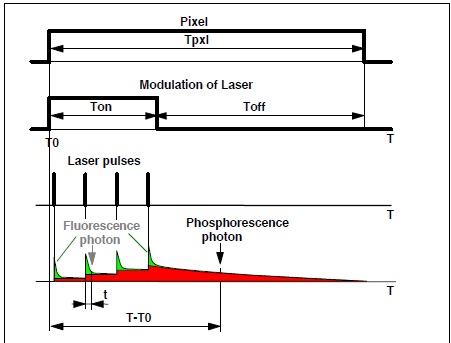

The general

principle of combined fluorescence and phosphorescence lifetime imaging is

shown in Fig. 1. A high-frequency-pulsed laser, in

this case the Ti:Sa laser of the LSM 710 NLO microscope, is used for

excitation. The laser is turned on for a short period of time, Ton, at the

beginning of each pixel [1, 3]. For the rest of the pixel time the laser is

turned off. Within the on-time the laser excites fluorescence, and builds up

phosphorescence. Within the rest of the pixel dwell time, Toff, pure

phosphorescence is obtained. Photon times are determined both with respect to

the laser pulses and with respect to the modulation pulse. The times from the

laser pulse, t, are used to build up the fluorescence decay. The

phosphorescence decay is built up from times from the modulation pulse, T-T0.

Fig. 1:

Principle of Microsecond FLIM

Because the

phosphorescence is built up over a large number of excitation pulses neither an

extremely high laser peak power is required, nor an extremely high fluorescence

peak intensity is generated. Saturation effects, both in the sample and in the

detector, are therefore avoided. Moiré effects in the image do not occur

because the laser-on/off modulation is synchronous with the pixel clock.

The system

architecture is shown in Fig. 2. The system uses a standard bh TCSPC FLIM

system that is connected to the LSM 710 NLO in the usual way [2]. To

generate the laser modulation signal a bh DDG‑210 programmable pulse

generator card is added to the system. The DDG-210 is triggered by the pixel

clock of the LSM 710. It delivers a laser modulation signal of programmable

width, which is fed back into the beam blanking system of the microscope, see Fig.

2, left. The feedback of the modulation signal requires a change in the

LSM 710 NLO laser controller. The changed controller is available via an

individual modification from Zeiss.

A second signal

is generated to indicate to the TCSPC module whether the laser is on or off. It

is used by the TCSPC module as a routing signal to send fluorescence and

phosphorescence photons into separate memory blocks [1]. The routing signal is

slightly delayed with respect to the modulation signal to account for the delay

in the opto-acoustic modulator (AOM) of the microscope, see Fig. 2, right.

Fig. 2: On-off modulation of LSM 710 laser. The pixel clock of the

LSM 710 triggers the generation of a laser-on pulse in the DDG-210 pulse

generator module. The laser-on pulse controls the beam blanking in the LSM 710.

The AOM of the LSM 710 responds to the beam blanking with a delay of a few

100 ns. A routing signal to the SPC-150 TCSPC module indicates when the

laser is on. Connection diagram shown left, pulse diagram right.

SPC System Parameter Setup

Combined FLIM / PLIM operation is obtained

without any hardware changes in the TCSPC module. It only requires appropriate

system parameter setup.

To set the parameters for FLIM / PLIM, open

the System Parameters panel of the SPCM software [1]. Click into the

Operation Mode field. Operation mode must be FIFO Imaging, see Fig. 3.

Fig. 3:

Operation mode

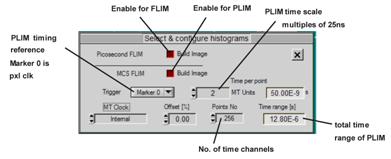

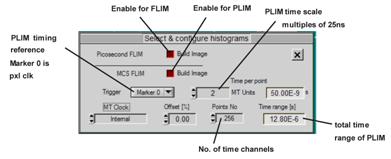

Open the Configure panel, see Fig. 4.

Enable both Picosecond FLIM and MCS (multichannel scaler) FLIM. Select the source

of the PLIM timing reference input. Timing reference for PLIM is the pixel

clock, which is identical with Marker 0. Select the number of time channels.

Recommended setting is 256. Select the desired time per point, or PLIM time

channel width. Time channel width is a multiple of the macro time clock (25 ns)

of the SPC module. The total time range of PLIM is the product of No. of

points and Time per point.

Fig. 4:

Defining MCS imaging, and MSC timing parameters

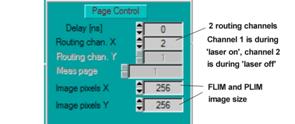

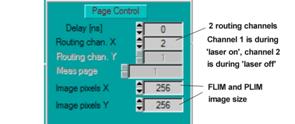

In the Page Control section of the system

parameters, set Routing Channels X = 2. One channel is for fluorescence, the

other for phosphorescence. Image pixels is the size of the FLIM image. The

typical value is 256 x 256. Larger and smaller images can be selected, see [1]

or [2]. Please note that the correct binning factors must be used in the scan

control parameters, see Fig. 6.

Fig.

5: Defining routing channels and FLIM / PLIM image size

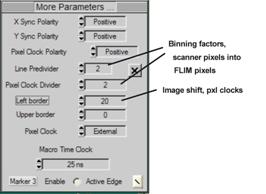

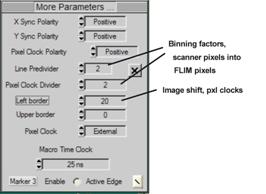

To access the scan parameters, open More

Parameters in the system parameters panel. Define the scan parameters. Typical

settings for the Zeiss microscopes are shown in Fig. 6. The Line Divider and

Pixel Clock Divider values define the binning factor of the LSM scan into the

FLIM image. For the standard LSM scan of 512x512 and a FLIM image of 256x256

the binning factors must be 2. Please see [1] or [2] for details.

Fig. 6:

Defining scan parameters and binning from LSM scan into FLIM / PLIM images

Display setup

Window Intervals

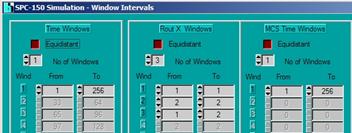

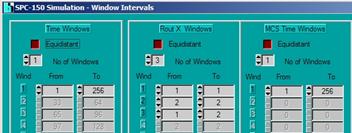

Open the Window Intervals panel. Set the

parameters are shown below. The Routing X windows define three data channels.

Window 1 contains the photons during the Laser On time; window 2 contains the

photons during the Laser Off time. Window three contains all photons. Thus,

an image displayed for Window 1 shows the essentially fluorescence, an image

displayed for Window 2 shows phosphorescence. An image displayed for

window 3 contains both fluorescence and phosphorescence.

Fig. 7:

Defining routing window intervals

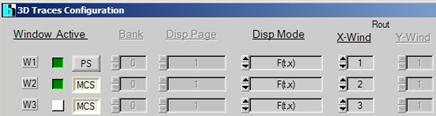

3D Trace Parameters

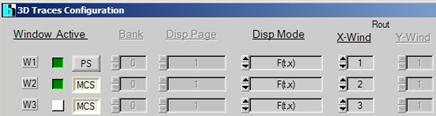

Open the 3D Trace parameter panel. Set the

parameters as shown below. The panel defines three images, one for Routing

window 1 (fluorescence, recorded by ps FLIM), one for Routing Window 2

(phosphorescence, recorded by MCS imaging), and one for the total luminescence

(Routing Window 3, recorded also by MCS imaging). The image for the total

luminescence has been turned off. To activate it click on the Window active

button.

Fig.

8: Definition of display windows

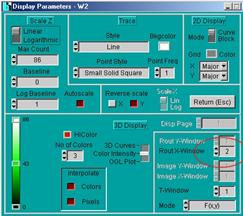

Display parameters

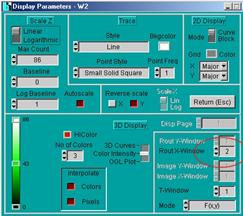

The display parameter setup is the same as

for standard FLIM measurements [1, 2]. There are separate display parameters

for the FLIM and the PLIM window. The figure below shows a display for the PLIM

window. Note that you can change the Routing X Window in the display

parameters. With window intervals as shown above in Fig. 7 Routing X Window 1

is for the laser-on time, Routing X Window 2 is for the laser-off time, and Routing

X Window 3 is for the entire pixel time.

Fig.

9: Display parameters

Saving the setup data

Please dont forget to save the setup data.

Select the Save panel and follow the instructions given in [1] or [2]. For

frequently used setups we recommend to define an entry in the Predefined

Setup panel. Please see [1] for details.

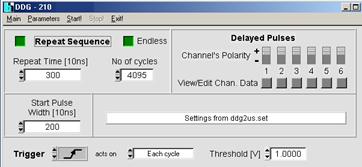

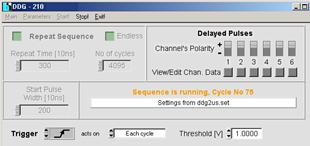

DDG Setup

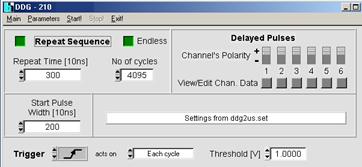

Start the control software of the DDG-210

pulse generator card. The general settings are shown in the panel below.

Repeat Sequence, Endless and Trigger on Positive Edge must be set.

Channel polarity is +. If the cables are connected as suggested in the system

cable plan the output of channel 1 controls the routing, the output of channel

2 the laser. You can use any other pair of outputs if you define the pulse

parameters of the channels accordingly.

Fig.

10: DDG software panel

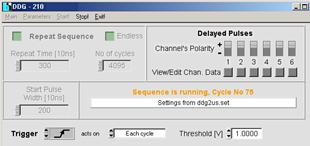

After starting the DDG software the DDG

automatically comes up with settings as they were used in the previous session.

If you want to run a PLIM experiment with the same excitation parameters as in

the session before there is no need to change anything. All you have to do is

to click the start button to start the DDG operation. See figure below.

Fig.

11: DDG software panel, DDG is running

To change the Laser-On duration, click on

the View/Edit buttons of channel 1 and channel 2. Fig. 12 shows examples for a

laser-on duration of 2 us (left) and 8 us (right). The numbers shown are

the start times and the widths of the pulses in 10 ns units. Note that the

routing signal is shifted by 800 ns with respect to the laser-on pulse.

This compensates for the delay of the AOM (acousto-optical modulator) of the

microscope, which is about 800 ns. Please see also Fig. 2.

Fig. 12: DDG,

defining the laser modulation time parameters for PLIM

Note that you need a pixel time of the LSM

that is at least two times longer than the Laser On interval defined in the

DDG.

Running the measurement

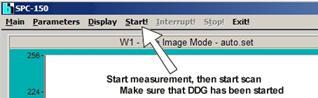

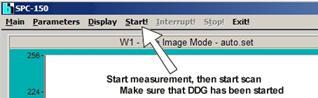

Starting the measurement

The measurement is started as shown below.

Fig.

13: Starting the measurement

Important:

When the measurement is started the SPC hardware waits for the beginning of a

new scan frame until it starts recording. The frame times used for PLIM can be

up to a minute or more. If the scan is already running when the measurement is

started it can take a long time until the recording begins. We therefore

recommend to start the measurement first, and then the scan in the LSM. The LSM

scan starts with a frame clock, thus the recording starts with the start of the

scan. Make sure that the DDG is running when you start the measurement.

Interpretation of count rates

The count rates present important

information on whether the intensity is within reasonable limits and the

recording process is running as expected.

Fig.

14: Count rates

When running PLIM experiments, bear in mind

that the count rates are determined over intervals of one second. Different

than for FLIM, the excitation laser is only active for a short period of time

at the beginning of each pixel. The sample may emit strong fluorescence during

the laser-on time, but only weak phosphorescence for the rest of the pixel

time. The fluorescence count rate (during the laser-on time) can therefore be

considerably higher than the count rate displayed. If it exceeds a rate of

about 5 MHz the fluorescence decay profiles may be distorted by counting loss

and pile-up effects [1]. If the fluorescence count rates are so high that the

detector overloads also the phosphorescence decay data may be impaired.

Stopping

the measurement

There are two ways to stop a measurement:

The measurement can be stopped after a defined acquisition time or by an

operator command.

Stopping after a defined time is used when

the intensities (photon numbers) in the data of several measurements must

remain comparable. To stop after a given time, define the desired Collection

Time and activate the Stop T button. Stop T and Collection Time can be

defined either in the main panel or in the system parameters, see Fig. 15.

Fig. 15: Setup

for stopping the measurement after Collection time

In most cases, however, intensity information

in FLIM / PLIM data is not relevant. It is then more convenient to turn off

Stop T and stop the measurement manually when a reasonable signal-to-noise

ration is reached. See figure Fig. 16.

Fig. 16:

Setup for stopping the measurement by the operator

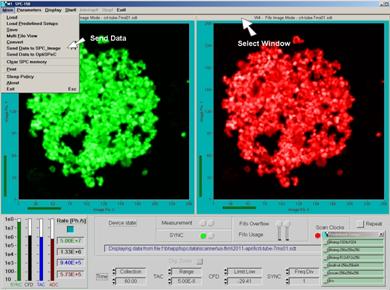

PLIM Data Analysis

Sending data to SPCImage

There are two ways to load data into the SPCImage

data analysis: An sdt file of the SPCM software can be imported via the

Import function of SPCImage, or the data can be sent to SPCImage by the Send

data to SPCImage function of the SPCM software [2].

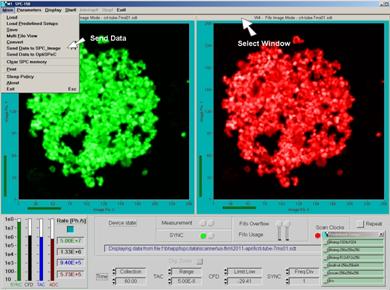

Note that the send function sends the

data shown in the active display window. To send phosphorescence data, click

into the top bar of the phosphorescence window, and then click on Send data to

SPCImage, see Fig. 17.

Fig. 17:

Sending data to SPCImage data analysis

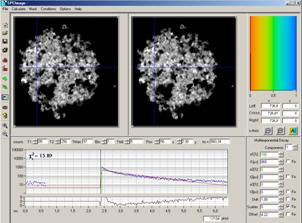

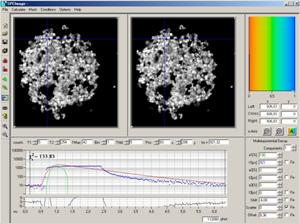

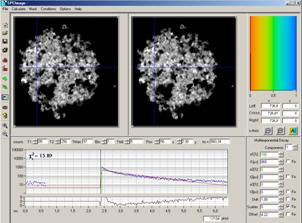

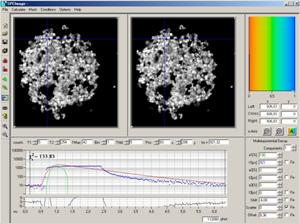

SPCImage will come up with the data

contained in the selected window (defined by the corresponding window

intervals). Depending on whether the selected display window was defined for

the laser-off time only or for the whole pixel time SPCImage shows only the

phosphorescence during the laser-off times, or the complete signal, see Fig. 18,

left and right.

Fig. 18: SPCImage after sending data from SPCM. Left: From a display window

containing data only within Laser-Off intervals. Right: From a display window

containing data of the whole pixel time interval.

The phosphorescence data in Fig. 18, left,

can be analysed without futher preparation. However, analysis will be performed

with an infinitely short instrument response (IRF) width. This will deliver the

correct decay time of a single-exponential phosphorescence decay. However, if

the phosphorescence decay is multi-exponential, the amplitude coefficients of

the decay components cannot be determined correctly.

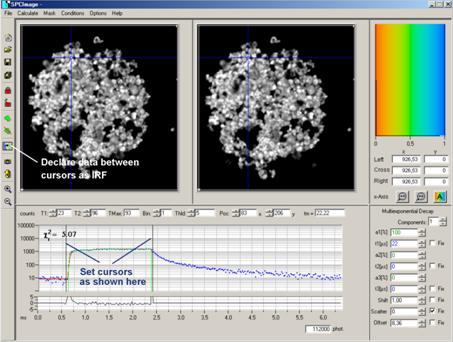

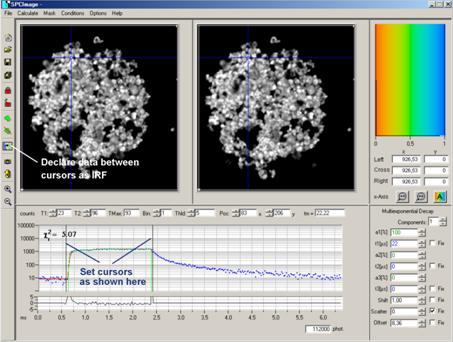

The data in Fig. 18, right, contain the

combined fluorescence and phosphorescence data. To analyse these data, a

reasonably correct IRF is required. This IRF can be measured, or created as shown

in Fig. 19. Place the cursors of the decay window at the beginning and the end

of the laser-on interval. Then click on the Curve-to-IRF button. This declares

the data in the cursor interval an IRF. The procedure works because (a) the

phosphorescence originates from the S1 population (indicated by fluorescence)

via intersystem crossing and (b) the intensity of the fluorescence during the

laser-on interval is high compared to the intensity of the phosphorescence.

Fig. 19:

Creating an IRF for PLIM analysis

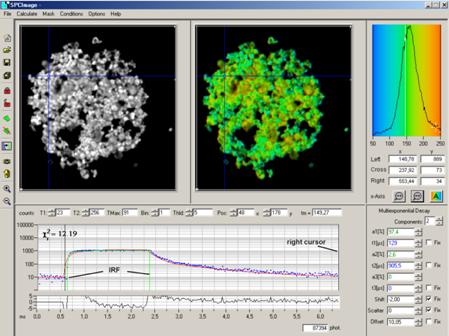

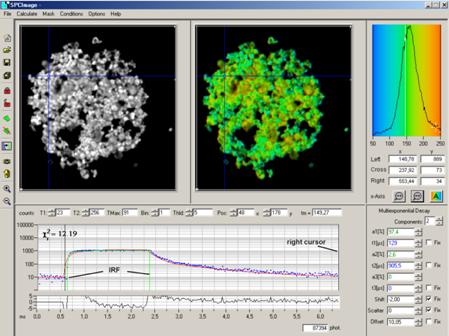

When the IRF has been defined, pull the

right cursor out to the last valid time channel. The rest of the procedure is

the same as for FLIM data [2]. Select the appropriate model parameters on the

right, and click on Calculate, Calculate decay matrix. This starts the

analysis in all pixels of the image. The result is shown in Fig. 20.

Fig. 20:

Analysed PLIM data

References

1. W. Becker, The bh TCSPC handbook. 4th edition, Becker & Hickl

GmbH (2008), available on www.becker-hickl.com

2.

Becker & Hickl GmbH, Modular FLIM

systems for Zeiss LSM 510 and LSM 710 laser scanning microscopes.

User handbook, available on www.becker-hickl.com

3. W. Becker, B. Su, A. Bergmann, K. Weisshart, O. Holub, Simultaneous Fluorescence and Phosphorescence Lifetime Imaging.

Proc. SPIE 7903 (2011)